Milestone Phase I |

|

Western Potash developed its detailed Final Engineering Report along with SNC_Lavalin. The Final Engineering Report outlines how the Company will develop the Milestone asset through reduced levels of potential production using innovative selective solution mining techniques and crystallization ponds. Reducing the Capital Costs and maintaining competitive operating costs were key goals throughout the process.

|

.jpg) |

Revolutionizing PotashThe purpose of the Milestone Phase I Project is to test and optimize the horizontal solution mining method in Saskatchewan, and to investigate how the method can be applied to full-scale potash production. This Phase I Project is truly innovative and could revolutionize the way potash is extracted in the province! |

.jpg) |

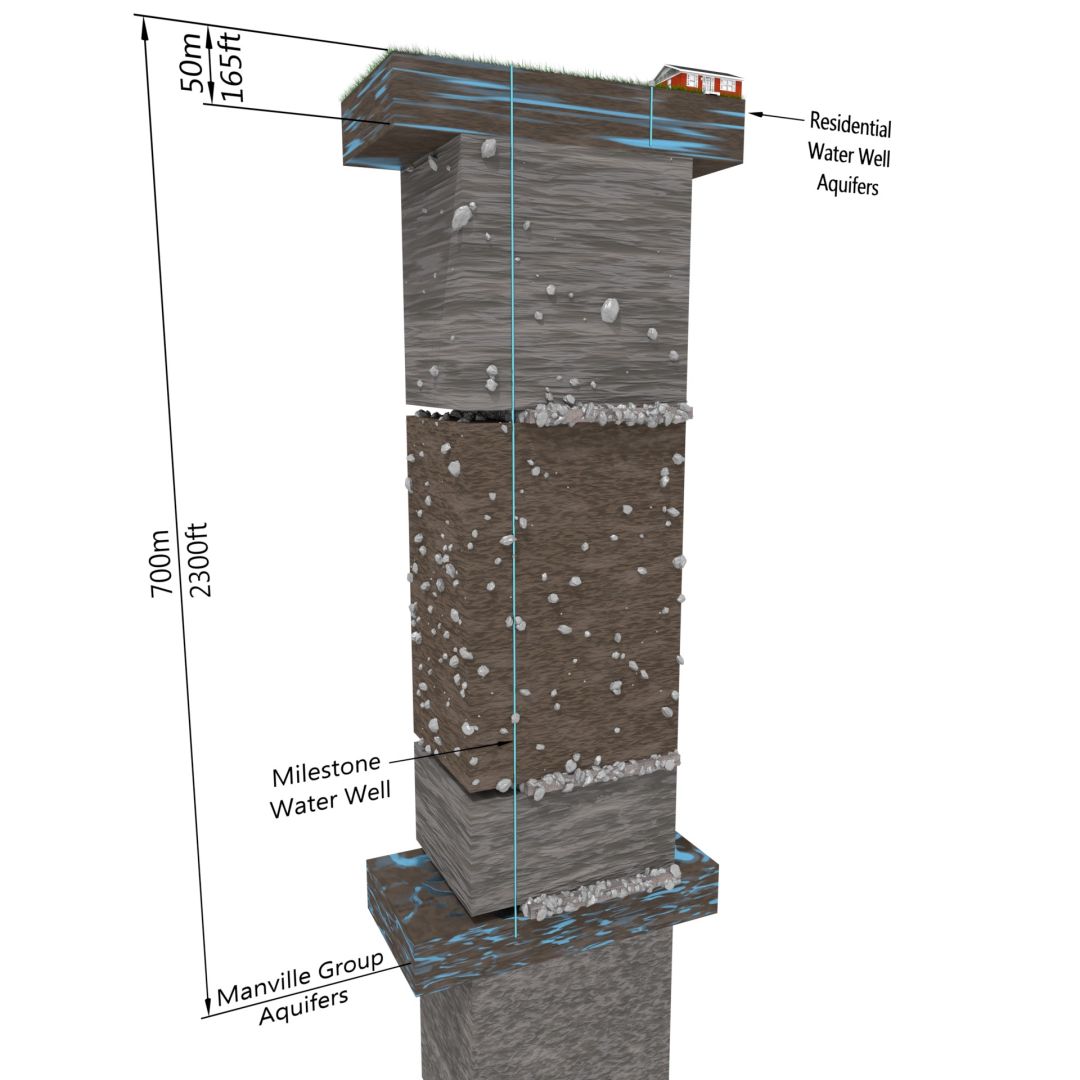

Key HighlightsThe Phase I Project Study is based on the mineral resources of the Belle Plaine & Patience Lake Members (target mining horizons) in Section 20, Township 14, Rage 17 west of the Second Meridian. |

Key Highlights of the Phase I Project Study:Projected Production Capacity

146,000 tonnes per year

Operating Life of Mine

40 years

Number of Caverns

6

Water Source

Brackish Water - Mannville Formation

Targeted Member

Patience Lake and Belle Plaine

Potash Grade

28% Mixed |

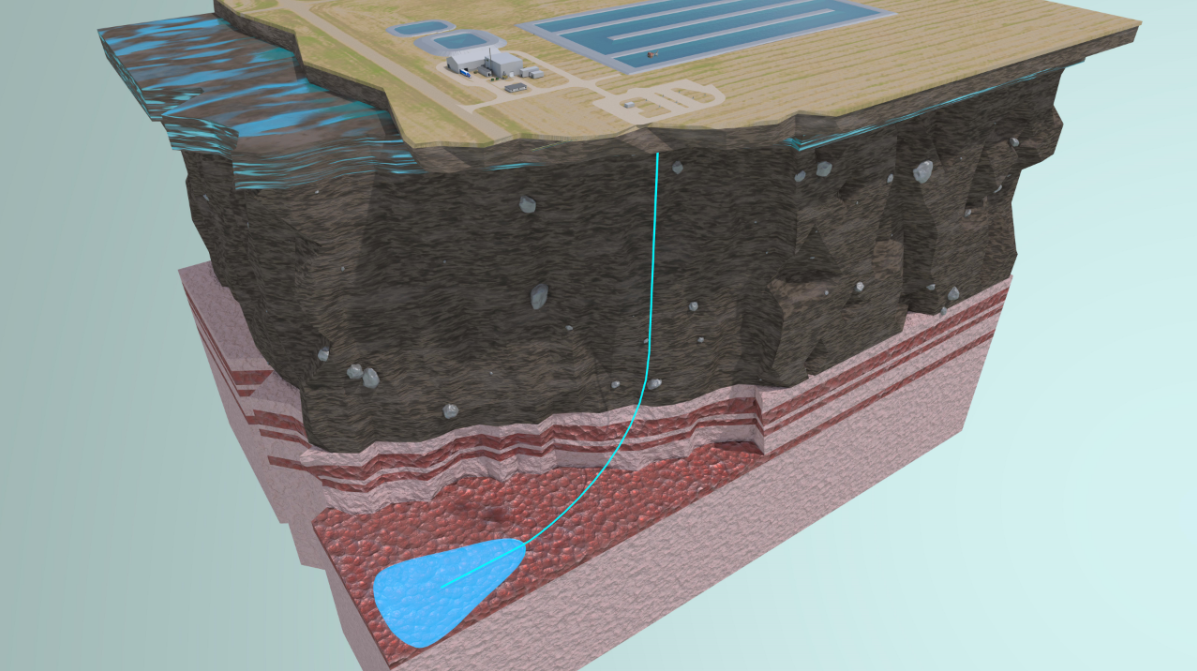

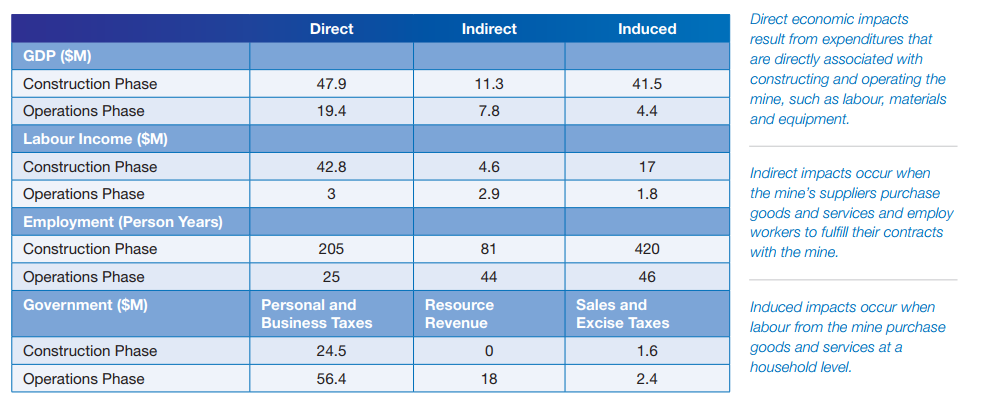

ProcessingThe processing plant is approximately 30 x 30 m and 15 m tall. The building houses the major processing equipment, which produces the hot fluid for injection, and dries the return crystal slurry to produce potash. A product storage and loadout building will hold approximately one week’s worth of potash, and is about 25 x 50 m and 15 m tall. There is also an administration building that will house the operations, maintenance, and administration staff. Small buildings for the boilers and electrical equipment are also located onsite. PondsThe 15-acre crystallization pond is located to the east of the process plant. Brine enters the pond at the southwest corner and is recovered from the northwest corner. The crystallization pond is designed to have one meter of freeboard to protect the surrounding area in the event of a rare storm event. The crystallization pond will utilize clay as a seepage free barrier between brine and soil or groundwater. Brine monitoring wells will be located around the perimeter of the crystallization pond. There will be a small storm water pond located north of the plant site that will capture any site runoff. In addition, a raw water pond which will hold approximately two days of water. UtilitiesRaw water will be piped to the site from a well nearby to the southeast of the plant site. Water is sourced from the Mannville aquifer about 800 meter below surface. Brackish water is extracted from the well, resulting in no negative impact on the local community. The well has been cased and cemented in place to protect ground water. Power is distributed to the plant and well pad by a combination of a 25 kV overhead line and buried cables. A 3” line will connect a natural gas regulator station with the larger transmission line ~4.5 km west of the site.  InnovationThe Milestone Project team is passionate about innovation! The challenging economic climate has meant innovative solutions were needed to bring a new project to market. The Phase I Project will use technology new to Saskatchewan – selective horizontal solution mining. This mining method has the potential to change the way potash is extracted in this area. The Milestone Project team envisions the simultaneous operation of three pilot production caverns. The horizontally drilled wells inject a Sodium Chloride (NaCl) saturated brine with a temperature higher than the in-situ rock formation temperatures. Potassium Chloride (KCl) is then selectively dissolved within the potash formation, leaving a lattice of NaCl behind. KCl rich brines are then brought to surface through each production well. KCl recovery is achieved through delivery of the resultant KCl-rich brine to a surface crystallization pond, producing 146,000 tonnes of standard grade MOP per year.  *This image is intended to provide a visual representation only and is not to scale, nor does it represent actual cavern shape or location* *This image is intended to provide a visual representation only and is not to scale, nor does it represent actual cavern shape or location*Environmental FootprintThe Milestone Project’s horizontal solution mining method uses saturated brine to extract potash, which means that the salt will not be brought to surface. Imagine that, a mine with no tailings pile! This method also requires about ½ the amount of water needed for a traditional solution mine. Our plans for the Phase I Project include using brackish water, which is not suitable for drinking, and recycling as much as we can. By bringing our wellfield and processing plant close together, we have created a relatively small footprint and has less impact to surroundings. Community InvestmentThe Milestone Project team understands that the mining industry has the potential to partner with communities to make great things happen. Throughout the construction and operation of the Phase I Project, our unwavering commitment lies in bolstering local initiatives that enhance community resilience. These initiatives will focus on vital aspects including water quality enhancement, research to inform sustainable practices, and strategies for consumption reduction. Simultaneously, we are dedicated to promoting energy efficiency and driving the development of renewable energy sources to lessen the community's carbon footprint. Moreover, we recognize the significance of waste reduction and will support projects that minimize waste production and optimize waste management practices. Our commitment extends to the improvement of local infrastructure, fostering long-term growth and sustainability. This includes enhancements to utilities, transportation, and the creation of green spaces. In parallel, we strive to cultivate a culture of innovation within the community, backing projects that encourage creative problem-solving and technological advancement. In essence, our comprehensive commitment spans various crucial domains: water quality, research, consumption reduction, energy efficiency, renewable energy development, waste reduction, infrastructure improvement, and innovation. Through these collaborative efforts, we aim to forge a lasting positive impact and contribute to the community's enduring well-being.  Economic BenefitLike all capital projects, the Milestone Project will have positive economic impacts to the Rural Municipality and the Province. Unlike other mining projects, the Phase I Project will be using innovation to drive environmental improvements in potash mining. The Phase I Project method will reduce impacts on water, energy consumption, subsidence, surface disturbance, produce less noise and generate fewer emissions. The Phase I Project will inject over $307 million into the economy and will benefit the community at the local, regional and provincial levels. The benefits come from direct employment, purchases, taxes, royalties and increases to GDP. Indirect and induced flow-on benefits will also be realized. Based on economic impact assessment tools, this table outlines benefits expected from our Phase I Project.

The Study produced preliminary process flow diagrams, site layout drawings, mining cavern and drill pad layouts, along with equipment lists and other engineering data. Estimates of capital and operating costs were developed to AACE Class 3 +/- 25% capital and operating cost estimate standards. The projected mining method, potential production profile and plan and mine plan referred to in the Study and this release are conceptual in nature and additional technical studies will be required in order to fully assess their viability. There is no certainty that a potential mine will be realized or that a production decision will be made. A mine production decision that is made without a feasibility study carries additional potential risks that include, but are not limited to, the inclusion of inferred mineral resources, which are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. Mine design and mining schedules, metallurgical flow sheets, and process plant designs will require additional detailed work and economic analysis and internal studies to ensure satisfactory operational conditions and decisions regarding future targeted production. To the extent that the use of the terms “ore,” “mineable” “production,” and “mining” occurs on this website or in the Study, its use is intended solely to differentiate between mineralized material (including dilution) above an economic cut-off grade and waste rock; there is no inference of mineral reserves. |